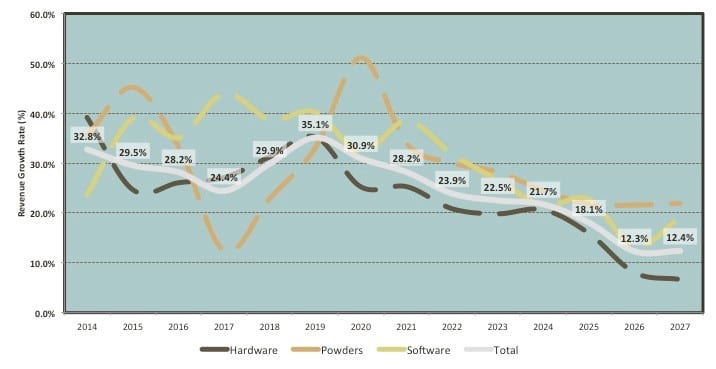

Charlottesville, Virginia: Industry analyst firm, SmarTech Publishing has issued its latest Metal AM Report, “Additive Manufacturing with Metal Powders 2018.” The report found that industry revenues resulting from hardware, materials, and software grew 24 percent in 2017 to exceed $1B for the first time, and that there is an increasingly positive long-term outlook based on the current environment which will reach $9.3B by 2027.

The perceived slowdown in the metal additive manufacturing market which was observed in late 2016 through the first half of 2017 appears to have been an anomaly powered by rapid competitive changes. SmarTech’s research found that the metal additive manufacturing market powered ahead in the last half of 2017 and is now poised for even larger growth for the future.

For more details on the new metal AM report go to:

https://additivemanufacturingresearch.com/reports/metal-powder-additive-manufacturing/

SmarTech is the metal additive manufacturing market’s leading source of industry analysis and market forecasting. The findings from the report are derived from the firm’s on-going data tracking and market modelling subscribed to by over 50 companies around the world.

About the Report:

This latest edition of SmarTech Publishing’s industry-leading market report on metal additive manufacturing technology and materials identifies how the metal AM market will develop in three distinctive technology areas to unlock pent up worldwide demand for digital manufacturing in markets both familiar and new to the world of 3D printing and additive manufacturing. With market tracking and modeling capabilities even further expanding, the report features more than 200 pages of analysis and data to present the latest ten-year outlook for metal AM.

Key metrics include:

- Metal powder shipments and revenues across eight leading metal material groups, including for the first time refractory metals, across markets, regions, and by print process

- Metal additive manufacturing hardware sales, installations, and revenues across technologies, adopting markets, regions, and more

- New capabilities in analyzing market shares by industry, hardware opportunities in various technologies within markets, material consumption and shipments by particle size distribution range, and more

In addition, the report provides a clear assessment of the powder supply chain and its key players, details the latest in competitive play in the market including announcements from HP and Stratasys to enter the metal additive manufacturing market, and updates in the shift to serial manufacturing applications in aerospace, automotive, energy, and other markets.

From the Report:

- Demand for lightweight metals continues to increase substantially thanks to growth in the established area of titanium AM, and also significant interest for aluminum AM from customers in the automotive and aerospace industries. Lightweight metals are expected to increase their total share of metal powder shipments to AM users slightly on a year-over-year basis through the forecast period, growing at a compounded annual rate of over 24 percent from 2017 to 2027

- The sale of powder bed fusion systems to the aerospace industry continued to be the largest opportunity for AM hardware sales in 2017, boosted significantly by demand for more expensive multi-laser systems and parallelized architecture systems being rolled out by Concept Laser, EOS, 3D Systems, and more. However, by 2027 the automotive industry is expected to become the second largest consumer of powder bed fusion technologies, growing at nearly 32 percent compounded annually

- With bound metal printing processes like metal binder jetting suddenly becoming a big target for development to suit the market need for low cost, high volume additive processes, the projected share of consumption of powder materials from all bound metal printing technologies is projected to grow from consuming just 5 percent of all powders shipped in 2017 to 21 percent of all powders shipped by 2027. Technology such as Desktop Metal’s Production Printer, to be released fully in 2019, holds the potential to significantly increase this estimate in the future pending real market acceptance

Projected Metal Additive Manufacturing Segment Growth Rates, by Primary Opportunity, 2014-2027(e)

Source: SmarTech Publishing

About SmarTech Publishing:

Since 2013 SmarTech Publishing has published reports on all the important revenue opportunities in the 3D printing/additive manufacturing sector and is considered the leading industry analyst firm providing coverage of this sector. Our company has a client roster that includes the largest 3D printer firms, materials firms and investors in the 3DP/AM sector.

For more details on our company go to www.smartechpublishing.com

To Purchase this Report:

Missy Wade

Press Contact:

Robert Nolan

804-938-0030