Charlottesville, VA – The boom in additive manufacturing will drive significant growth in the area of metal powders optimized for use with 3D printers, according to a new industry report and forecast just released by SmarTech Markets Publishing. The report is titled “Additive Manufacturing Opportunities in the Metal Powders Industry.” SmarTech’s expectations are that 3D printing/additive will consume around $520 million in metal powders by 2019 growing to $930 million by 2023.

About The Report

Additive Manufacturing Opportunities in the Metal Powders Industry is the latest report on advanced manufacturing from SmarTech Markets Publishing. The report is authored by Senior Analyst Scott Dunham, a seasoned industry analyst in the 3D printing business, who has been covering the space for years. This report compliments SmarTech’s report on polymers and plastics used in additive manufacturing, which was released in August 2014. The two reports together provide the largest accumulation of knowledge and market forecasts for additive materials in existence.

Additive Manufacturing Opportunities in the Metal Powders Industry provides granular ten-year forecasts of titanium, stainless steel, nickel alloys, aluminum, cobalt chrome, copper alloys and previous metals, with individual projections of these metals, with individual breakouts for additive metal manufacturing for aerospace, automotive, medical, dental, service bureaus and other applications.

This new SmarTech report also provides analysis of the product market strategies of leading firms active in this space demonstrating how 3D printing leaders expect to generate profits from metal printing in the next decade. It also analyzes the supply chain for metal powders in additive manufacturing, provides an overview of current material demands and applications, and determines demand and market opportunity for specific metals as well as vertical markets utilizing metal additive manufacturing.

From the Report

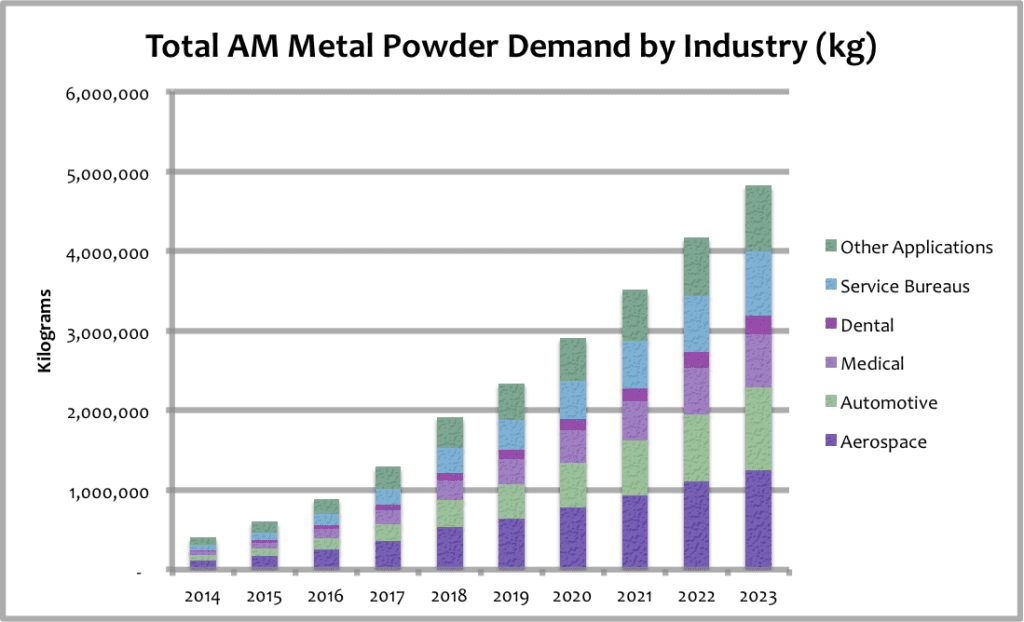

The metal powder industry, historically serving traditional powder metallurgy production techniques, is embracing additive manufacturing as a growing source of demand over the next ten years, with demand for metal powder used for 3D printers growing to 4.8 million kilos in 2023. Nonetheless, industrial metal 3D printing still has a lot of developing left to do, according to SmarTech Senior Analyst Scott Dunham.

Leading the development of manufacturing metals parts with metal powders has been the aerospace industry, which SmarTech expects to consume around $150 million in 3D metal powders by 2019. Aerospace has been the pioneer for metal additive manufacturing in high value applications. Meanwhile, the use of metal printers in service bureaus are creating more and more demand for metal powder material, as bureaus seek highest possible utilization rates for their printers to control manufacturing costs. By 2019, SmarTech expects service bureaus to consume almost $100 million in metal powders for 3D printing.

The supply chain for metal powders for additive manufacturing is potentially robust, as production processes for metal powders have been utilized for decades, with hundreds of thousands of tons of powder being supplied to manufacturers across the globe each year. Despite the perception that 3D printable powders themselves are difficult to produce, powder suppliers actually understand the necessary requirements for powder very well.

The future is very encouraging for metal powders for use in 3D printing, however, as extensive investment in R&D for self-monitoring and reporting in metal 3D printers is taking place. This will lead to quicker qualification of metal parts printed via additive manufacturing in high value applications.

For more details on this report see: https://additivemanufacturingresearch.com/reports/additive-manufacturing-opportunities-in-the-metal-powders-industry-a-10-year-market-forecast/

About SmarTech:

SmarTech offers the best in industry analysis and forecasting for the 3D printing/additive manufacturing and advanced manufacturing sectors. Our published reports and customized consulting work provide clients with guidance on the direction that 3D printing is taking and how to capitalize on available opportunities.

See https://additivemanufacturingresearch.com for more detail on our reports and other services.

See www.smartechpublishing.com for more detail on our reports and other services.

For further information on this report contact:

Lawrence Gasman

lawrence@smartechpublishing.com

434-825-1311